Logistics and Handling Solutions (LHS)

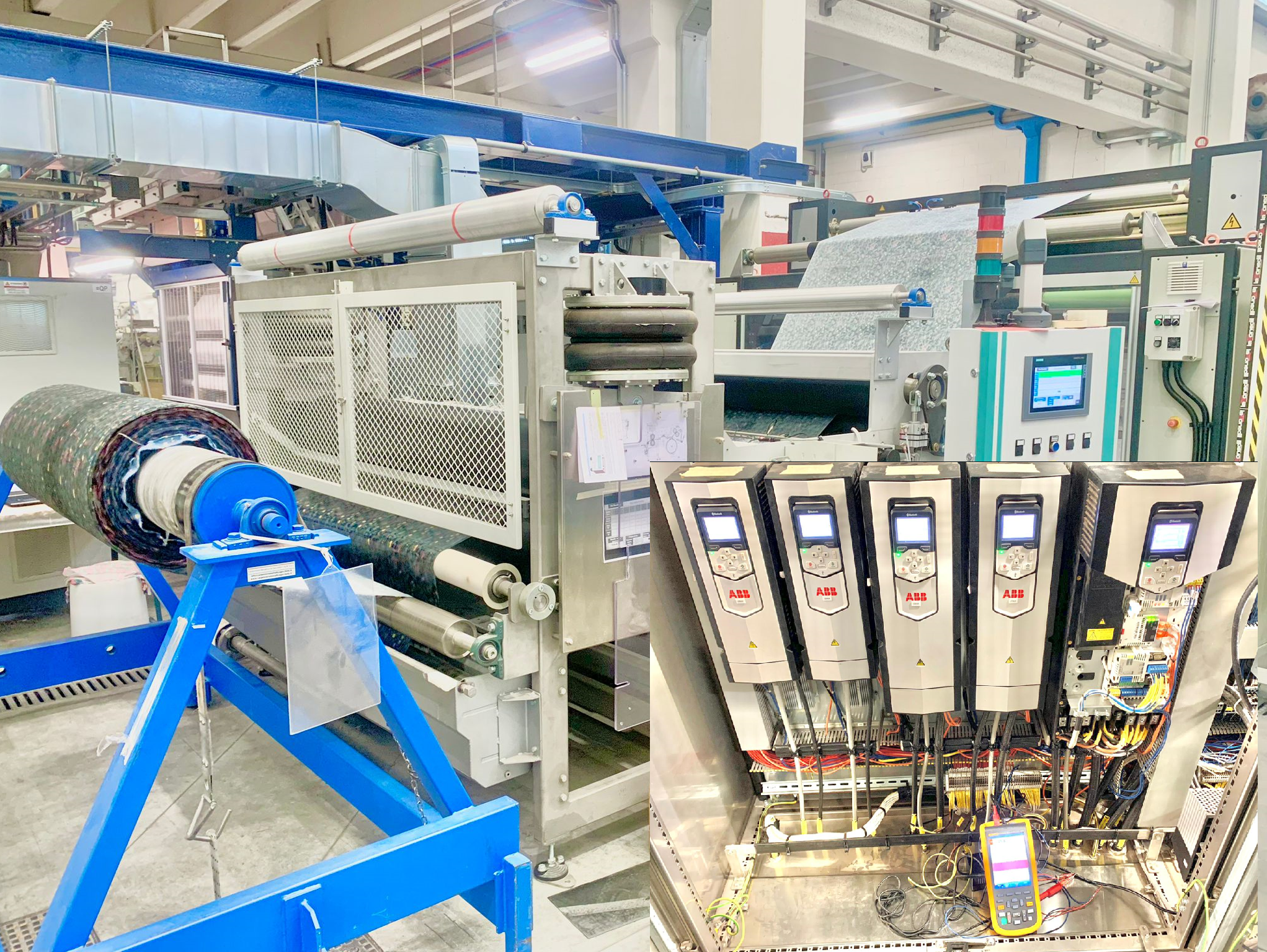

The growing importance of integrated logistics as a company added value. In the overview of supply chain management systems, the logistics side has always occupied a position of primary importance both in terms of its role as supplier of operations systems and its, more well-known, role of distribution management. Our technicians have the skills and many years of experience gained in the field of logistics and material management such as conveyor belts, etc.

Manufacturing Machine Devision (MMD for OEMs)

Original Equipment Manufacturers (OEMs) provide standard solutions to a particular manufacturing requirement, such as packaging machines, material handling systems or air handling units. Drives are installed and supplied as part of the overall equipment. Guru Automation is providing the different services to the OEMs which allows our clients to improve their control system and to be updated with latest technology provided by automation devices manufacturer.

Manufacturing Execution System (MES)

MES System is a manufacturing efficiency and execution platform which allows for the collection of data from the machines, or entire production line, analyzing and displaying them in a user-friendly manner. MES software is implemented to make operators’ jobs more predictable and help managers to undertake more insightful decisions for faster and better production. We are supporting the company’s to implement MES systems to manage their production and significantly improve the performance of its production plants and have complete control from the order, raw material up to the finished product warehouse and plan production in the near future.

Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software solution that provides visibility into a company’s entire inventory and manages the supply chain’s order fulfillment operations from the distribution center to the store shelf. Warehouse Management Solutions (WMS) also enable companies to optimize efforts, space utilization and equipment investments by coordinating and optimizing the use of resources and material flows. Specifically, WMS systems are designed to support the needs of an entire global supply chain, including distribution, manufacturing, service, and asset-intensive activities.

Recently we are devoloping the new programming architetture for OEMS of warehouses to reduce the software devoloment time and in turn automate the development of control software.

Project Solutions

Our company works based on the projects and provides services all around the world. Our teams of highly skilled engineers contribute to the success of your projects. Thanks to the extensive field background of its teams, Project Solutions can fully understand the needs of its clients. We have forged longstanding professional relationships and developed an the network to ensure that competent staff can be deployed worldwide.

Claculation Pre-quotations

We are providing a priority service to our historical customers who can roughly calculate the project costs in complete autonomy without wasting time requesting quotes. For those who have password access, they can calculate the cost of the development service in complete autonomy control software and/or HMI/SCADA software for managing the machine interface before sending the official request for a precise and detailed quotation. To access the pre-calculation pages just click on the following link. Click here!!

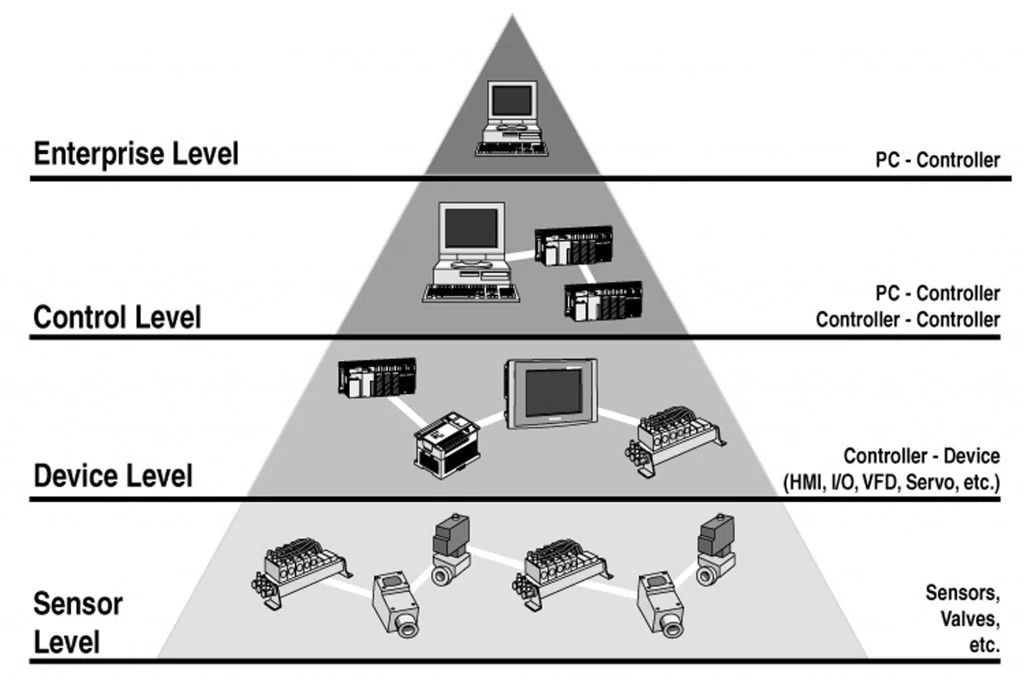

Control System Integration

- Development of control system specifications

- Hardware requirement specification and acquisition

- Core engineering capability in Critical Process Automation & Digital Transformation solutions

- Authorized Solution Provider of Process Measurement & Control System OEM’s – Rockwell Automation for industrial automation & information system solutions

- Global footprint of project executions in Asia-Pacific, Middle-East, Africa, Europe & Americas.

- Functional Safety Consultancy for Critical Process Safety Systems